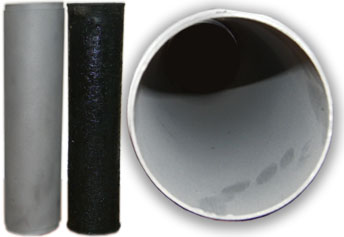

Progressive cavity pump manufactures are faced with increasing pressure to offer customers with aftermarket services and reduce the total cost of ownership. Power sections offer the most cost effective and environmentally friendly solution to reduce OEM production costs, provide aftermarket options and to improve the supply chain challenges with stators. Many OEM's have yet to realize that there is a technology that can safely and affordable remove even the most difficult bonding agents and rubber for today's cutting edge power section stators. With our proven proprietary technology, OEM's will have an advantage over their customers and stop the profit loss from aftermarket powersection providers. Our technology has been proven to break any bond and remove any elastomer.

We are pleased to be able to provide progressive cavity pump OEM's with a significant technology advantage.